PROJECT 1 – Robotic Automation & Integration

Problems:

- This customer was previously straightening their small diameter pins manually, which takes a considerable amount of time due to the extreme precision necessary. This need for such fine adjustments caused slow lead times.

- Meanwhile, they could only produce a certain volume of the pins, which cannot fulfill their customers’ needs

- Under some circumstances, their customer had challenges of the pin not working, after inspection, they find that the pin is not their product and customer desired for refund for counterfeit product

Solutions:

- Our automatic straighteners programming allows it to meet the precise measurements necessary to straighten their small diameter pins with a minimum amount of labor involved.

- Automation greatly reduces cycle time and in turn allows for more production capabilities

- Laser Printed QR code on the end of each pin for tracking the batch number of the product

- Use secondary HMI to enable the customer to have full control of the automation and change parameters as needed

Benefits:

- Improved the customer’s delivery time from 10 weeks to 4 weeks

- Increased the customer’s potential production volume

- Identify pins that are not the customer’s products

- Customize to fit the needs of the customer

- Brings more flexibility and capabilities to the customer

PROJECT 2 – Time Efficiency Solution

Problems:

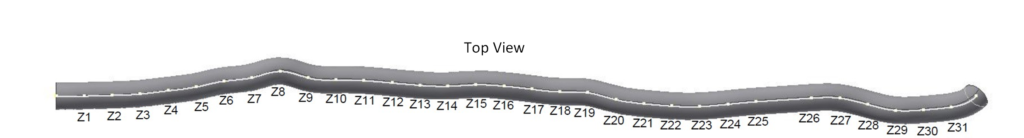

- The customer has complicated and challenging parts to straighten (e.g. 40 feet long tubes)

- These parts have inconsistent geometric conditions

- Current method of straightening takes over 30 minutes per part

Solutions:

- We analyzed the parts and set up various measurement strategies based on the different geometric conditions encountered

- We used an auto changeover machine to enable lights out operation

- We provided part marking of serial # and batch # to make tracking parts simple and better organized

- We customized software designs for variable tolerances to manipulate geometries

Benefits:

- Our machine can improve material handling ergonomics

- Our machine’s automation can improve productivity and efficiency

- Our machines can cut the straightening time to just under 10 minutes per part

- Our machine can provide more consistent quality control compared to manual straightening

PROJECT 3 – A Combination Solution

Problems:

- The customer has 2-3 machines that are close to the end of their service life

Solutions:

- Modern style machine aligns with faster cycle time and higher production efficiency

Benefits:

- One automatic machine has the same production efficiency as 2-3 of their old machines had

- It has automatic change-over functionality

- It can detect cracked parts without manual intervention

- The history table can store data and speed up the process and cycle time

- It’s cost-efficient combining the capabilities of 2-3 machines into 1

PROJECT 4 – Precise Solutions

Problems:

- The customer’s machine can only straighten their workpieces within a tolerance of .010 inch

- The customer’s process requires multiple straightening

- The customer’s machine is not as precise as ours: it does not have a gauge and cannot measure stroke depth

Solutions:

- Our machine can perform tolerance less than .002 inch

- Our engineer can measure TIR at multiple points on the workpieces, apply the points, and investigate general curve in the workpieces

- It’s easier to visualize before straightening

Benefits:

- Our automatic style machine can measure TIR at multiple points within 10 seconds

- Our machine can significantly cut down manufacturing time

- Our machine can increase the precision of measuring the workpieces

- Our machine can decrease the tolerance of straightening

Fun Projects – Coat Rack

One of our CNC Machinists, Alex, designed and machined this “MAE-EITEL” Coat Rack for our President, Norm, as a Christmas Gift!!! Read their statements below

BTW … Do YOU have any AWESOME ideas for a special gift for your supervisor, co-workers, or even your customers to show your appreciation, as well as brand your products or your companies?

Give us a call: We can CUSTOMIZE any kinds or shapes of metal products for YOU!

” I came up with the idea with some other co-workers, made a drawing, used the available material on the floor, and machined on our CNC mills. We designed this unique gift for our President in appreciation for his great support and opportunities MAE-Eitel offers us employees.”

– Alex, CNC Machinist

” I have a special appreciation for the intrinsic beauty of functional work. Seeing the tool paths where the mill cut through the steel and understanding the set-up, programming and work that goes into manufacturing a piece such as this made it one of the best gifts that I have received.”

– Norm, President